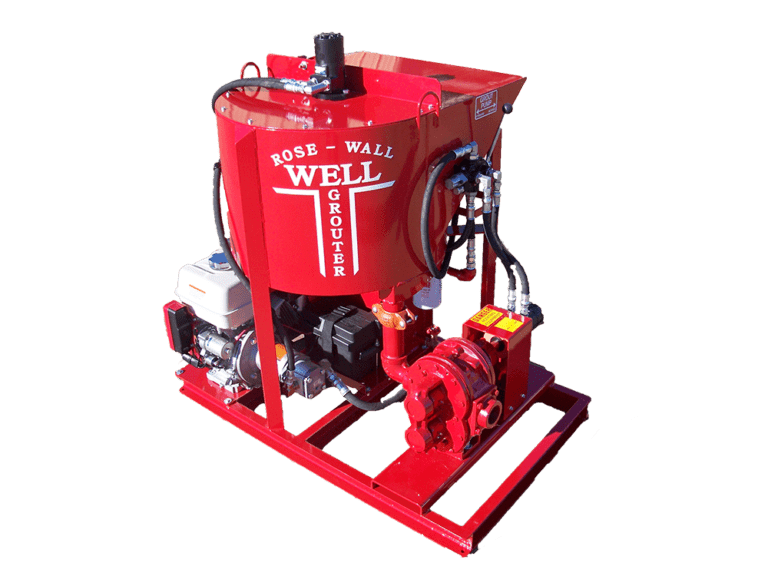

At Rose-Wall, we manufacture well drilling equipment designed by professional well drillers, for well drillers. Whether you need a grouter, water truck or rig tender, we will build the equipment to meet your specific needs.

Customize your Grout Machine for maximum efficiency on the job site.

The RW 4100 OB delivers consistent grouting with a 13 HP Honda engine and hydraulic drive. Its 41-gal hopper and high-performance pump ensure a uniform mix and flow. Constructed with durable 10-gauge steel.

Engineered for robust performance, the RW 5800 grouts in tough conditions. Its heavy-duty engine, hydraulic drive, and large hopper deliver precise control and uniform mix, while a powerful pump and rugged steel frame ensure durability.

Engineered for heavy-duty grouting, the RW 11600 PCPDH delivers exceptional performance. A robust engine with precision hydraulic control powers an advanced mixing hopper and high-performance pump, while rugged steel construction ensures lasting durability.